Applications

- Spans of 10 to 40 feet typical

Panel-Lam bridges feature a thin profile and a superior strength-to-weight ratio which is ideal for short span applications. Decades of design evolution make this a proven, economical and easy to build choice for low volume bridge sites.

The Panel-Lam bridge system rivals any contemporary material, including reinforced concrete, steel and plastic. Our kit features shop-fabricated components for accelerated bridge construction. Panels are custom-built for each project and the width can be adjusted for easier handling.

The simplified installation process reduces road closures and detour delays. This makes the Panel-Lam an ideal bridge for local, county and forest roads, private driveways or temporary bridges.

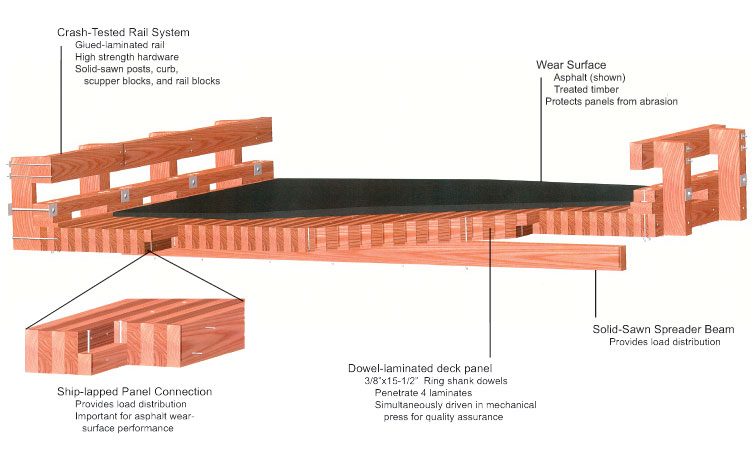

The Panel-Lam features individual timber planks assembled with spikes into a slab span. Plank laminates are pressure treated prior to assembly for maximum durability. Assembled in a press, the number of laminates can be adjusted to achieve the desired panel width. The panels are interconnected into one integrated system that effectively interfaces with many wear surfaces (typically asphalt). Panels can be installed over any foundation type.

Panel-Lam design is covered by AASHTO LRFD standards. The USDA Forest Service and other state agencies have also adopted standards for the Panel-Lam bridge system.

Designs for AASHTO HL-93 and special permit vehicle combinations as well as U-80 and U-102 logging trucks are all available.

TL-2 and TL-4 railing kits meeting the requirements of NCHRP 350 are available. Railings connections are integrated into the panel details.